Prefabrication has become an increasingly important part of how we work at Teknisk Isolering AS. With a modern workshop and advanced production equipment, we prefabricate cladding, enclosures and insulation boxes for industry, food production, energy and building/HVAC projects.

But why do we do this? And what does it mean for our customers?

1. Because quality starts before installation on site

When we produce components in our workshop, it is done under controlled conditions. This ensures:

-

Precise cutting and forming

-

Consistent, high quality across all components

-

No improvisation on site

-

Reduced risk of errors and deviations

For industrial projects, food production facilities and energy installations—where requirements for quality, hygiene and operational reliability are high—this is critical.

Prefabrication directly supports our ambition to deliver quality and precision, an area where both our strategic work and SWOT analysis show that we are strong and continue to develop further.

2. Faster installation – and shorter project duration

Time spent on site is expensive. Both we and our customers know this.

When components are fully produced in the workshop:

-

Installation is faster

-

Logistics become simpler

-

Interference with other trades is minimized

-

Costly downtime and waiting time are reduced

For industrial pipe contractors—who are often our main contractors and partners—this means one thing: projects can be delivered on time, with lower risk and fewer surprises.

3. Cost efficiency – fewer hours, less waste

Prefabrication is not only about speed and quality. It is also about economics:

-

Reduced material waste

-

Fewer working hours on site

-

More accurate quantities and quotations

-

Predictable production and improved cost control

This supports our strategic goal of increased profitability per project and better financial control throughout project execution.

4. Tailored solutions for complex challenges

Many of our projects are complex: heat exchangers, pumps, tanks, cooling systems, ventilation ducts and piping in all shapes and sizes.

Prefabrication allows us to deliver:

Cladding

Manufactured in aluminium, stainless steel, galvanized steel, aluzinc or plastic-coated materials – providing protection against weather exposure, corrosion, mechanical stress and moisture.

Enclosures

For tanks, valves, pipes and components – combining insulation against heat, cold and noise, while meeting HSE requirements.

Insulation boxes

For pumps, valves and heat exchangers – designed with inspection hatches and solutions that make maintenance easier and safer.

These products require both technical expertise and high precision. This is where we have clear strengths—across production, customization and on-site delivery—as confirmed by our SWOT analysis.

5. For industrial pipe contractors: a partner, not just a subcontractor

In most projects, the industrial pipe contractor is the main contractor. Prefabrication makes us a stronger and more reliable partner:

-

More accurate input during the estimation and tender phase

-

Better control of their own quotations

-

More predictable deliveries

-

Reduced risk in both design and production

-

Added value they can include in their own tenders

This aligns with our strategic ambition to be the most reliable partner for industrial pipe contractors in Norway.

6. Where do we use prefabrication?

Prefabrication delivers the greatest value where requirements are high and mistakes are costly:

-

Process industry and energy

-

Food production (strict hygiene requirements, 24/7 operations)

-

Shipyards and maritime industry

-

Factories, power plants and data centers

-

Building and HVAC installations

This is about more than efficiency—it is about safety, operational reliability and predictable deliveries.

7. What this means for you as a customer

When you choose prefabricated solutions from Teknisk Isolering AS, you gain:

-

Faster delivery

-

Lower risk

-

Higher quality

-

More predictable costs

-

More robust documentation

-

A partner who contributes before, during and after the project

And perhaps most importantly:

You receive a solution that lasts—technically, economically and in terms of quality.

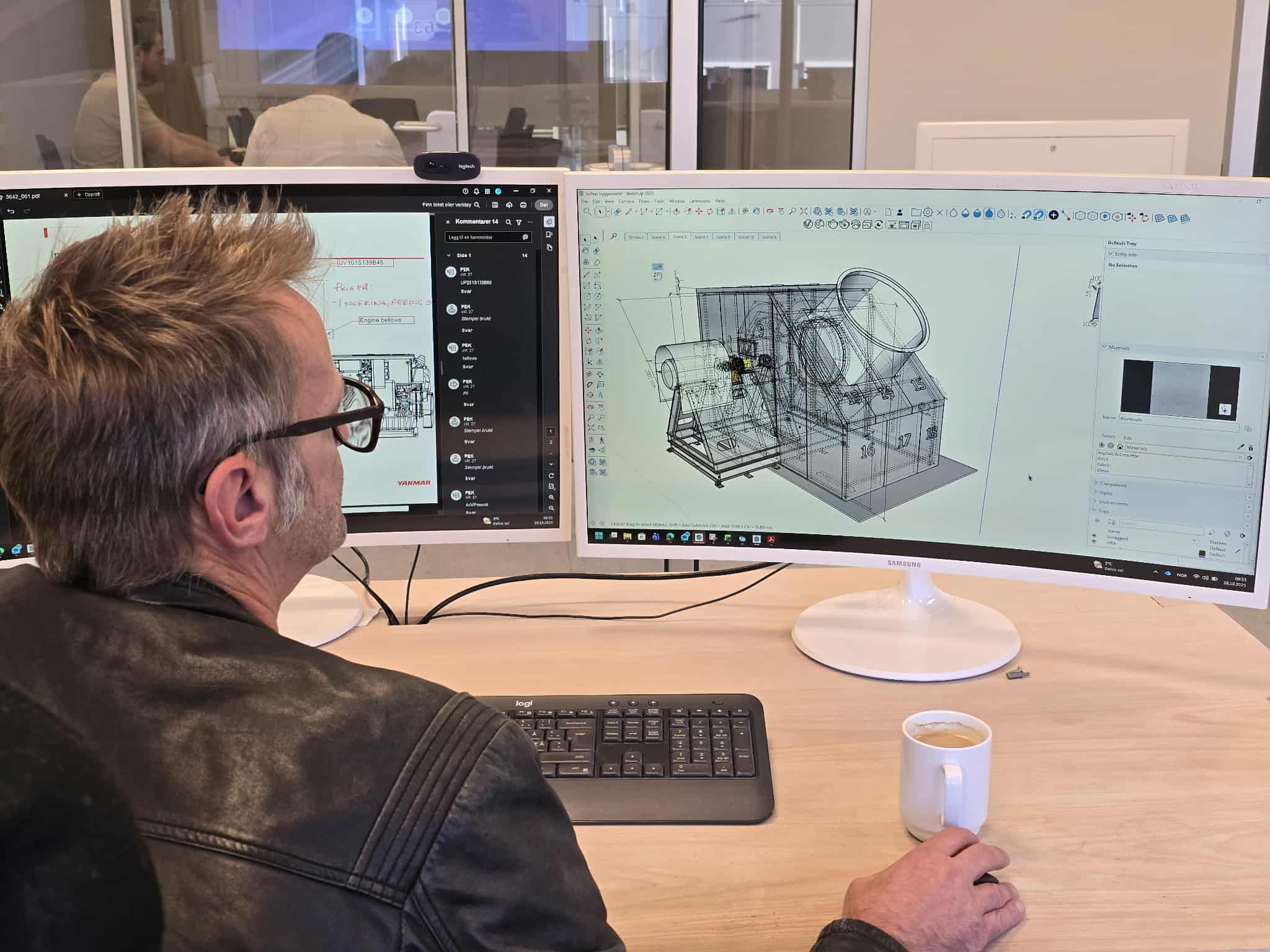

For us, prefabrication is not just a method of work—it is a quality commitment. The images below are taken directly from our own production and show how we combine precision, technical expertise and modern equipment to deliver complete units that:

-

Fit perfectly

-

Enable rapid installation

-

Reduce risk

-

Ensure high delivery reliability

.png?width=1200&length=1200&name=Kvalitet%20(1).png)

.png?width=1200&length=1200&name=Mabi%203000%20(2).png)

Contact us – and let’s find the right solution

Do you have a project that could benefit from prefabrication, or would you like to learn more about how we work?

Get in touch for a no-obligation conversation.

We tailor solutions to your needs and identify the most efficient path from concept to completed installatio